详细内容:

Product Introduction

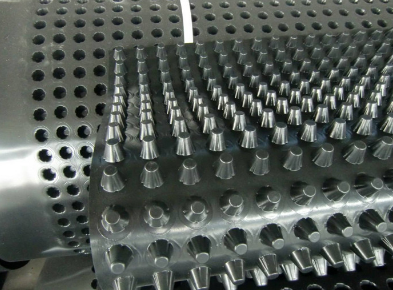

By using special processes such as extrusion adsorption, the closed protruding cylindrical or semi-conical shells are formed, creating a continuous film and shell with three-dimensional space and certain supporting rigidity, allowing liquids and gases to flow and be discharged within it. It is a functional material with many potential functions. During use, it is very convenient to construct a suspended layer, forming drainage and exhaust channels, and achieving the functions of sound insulation and vibration isolation. It can be widely used in the field of civil engineering and construction for drainage and ventilation within the roof system of buildings, drainage protection in the waterproofing system of building basements, moisture-proof and heat-insulating protection of indoor floors, and drainage protection in highway and railway tunnels, etc. Today, with urban land, space and material resources becoming increasingly precious, plastic drainage boards offer valuable options.

Performance features

Low cost and high efficiency; Durable and long-lasting; Resistant to chemical corrosion and plant root penetration; Diversified application functions; The installation process is simple and the quality is easy to guarantee.

Function and application

Waterproofing systems for highways and railway tunnels, underground waterproofing systems, green planting boards on building basements, and waterproofing and drainage projects for building roof gardens, etc.

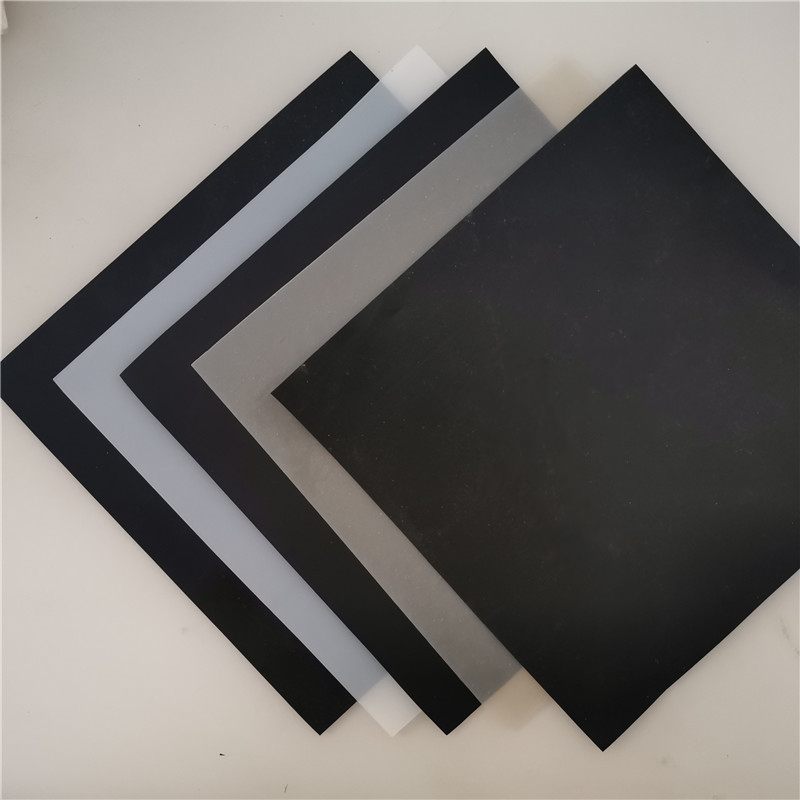

Product specifications

The thickness of the sheet is 0.8 to 2.0 mm, the height of the protrusion is generally 8 cm to 20 cm, the width of the product is 2 to 2.5 meters, the sheet material includes HDPE, EVA, etc., and the length is according to the user's requirements.

Construction Specifications

1.Please store the drainage board in a dry and well-ventilated environment, protect it from direct sunlight and keep it away from fire sources.

2. Please place the drainage protection boards upright or flat. Do not tilt or cross them horizontally. The stacking height should not exceed three layers and heavy objects should not be stacked on top of them.

3. When laying, it should be flat and natural, and laid along the slope or in the direction of water flow.

4. When laying a single geotextile, the overlap should be 150cm. The overlap should be compacted with glue or sand to prevent movement, and then backfilled. The backfill soil in each layer should be compacted before proceeding to the next step. The backfill in each layer must be compacted.