详细内容:

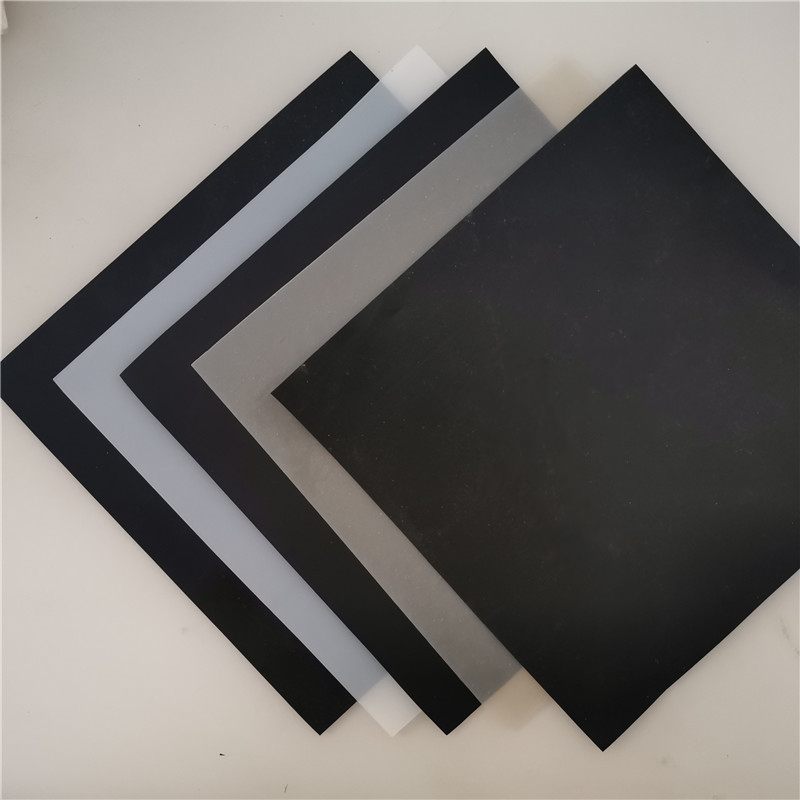

Product Introduction of EVA Tunnel Waterproof Board

The production process of EVA waterproof board adopts the domestic two-stage co-extrusion single-pole extrusion method. It is made by adding reinforcing agents and antioxidants to the raw resin EVA, followed by heating and melting, plasticizing, extrusion molding, and traction to form the board. It can also be thermally synthesized with geotextile (signal layer) with lifting straps to form a composite waterproof board, or it can be produced by extrusion calendering. The resin is melted and plasticized by the resin extruder, and the molten sheet blank is extruded from the die opening of the die head slit and fused with the lifting strap. After being calendered and cooled by the roller, it forms a smooth film, or it is fused with the geotextile with the lifting strap, and then calendered and cooled by the roller to form a composite waterproof board.

Performance features

The main function of the EVA tunnel waterproof board with lifting straps is to prevent the leakage of liquids and the volatilization of gases. The role of the waterproof board in rock engineering is mainly to prevent seepage and isolation, but it also plays a role in reinforcement and protection. It is mainly applied in the anti-seepage of earth-rock DAMS, rockfill DAMS, masonry DAMS, concrete DAMS, tailings DAMS, sewage reservoir DAMS, channels, liquid storage pools and other projects, anti-seepage linings of subways, basements and tunnels, anti-seepage of highway and railway foundations, and is used in conjunction with geotextiles such as long-fiber geotextiles and bentonite waterproof blankets in sanitary landfill sites.