详细内容:

Product Introduction

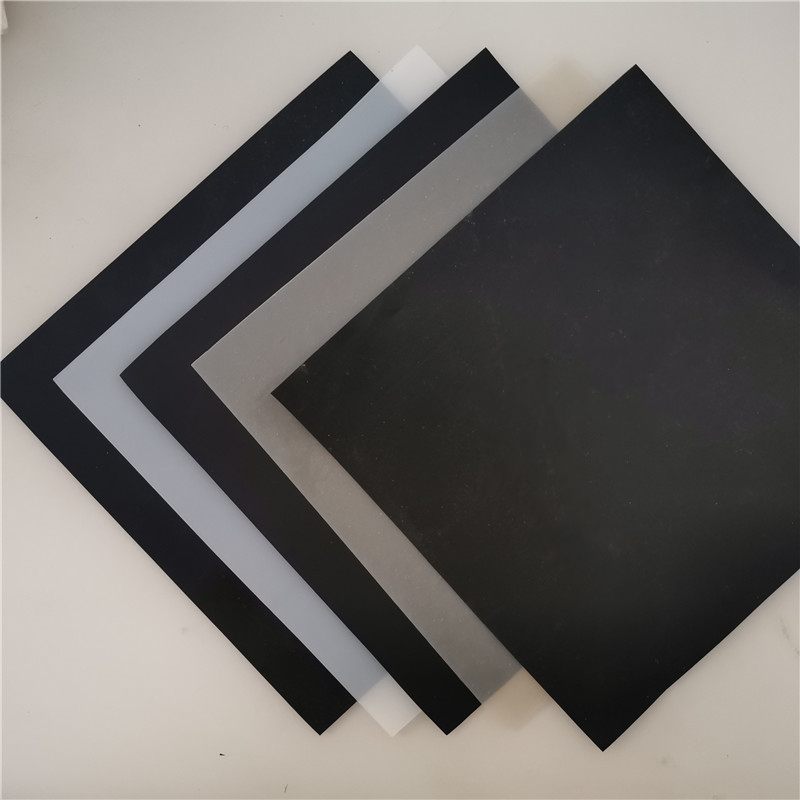

HDPE smooth geomembrane is one type of geosynthetic material. The application of geosynthetic materials originated in the 1950s. Domestic geomembrane is one of the Eighth Five-Year Plans of the country. HDPE geomembrane is a waterproof and barrier material produced from (medium) and high-density polyethylene resin. Geomembrane with a density of 0.94g/cm ³ or above.

Performance characteristics of HDPE smooth geomembrane

It contains no chemical additives and has not undergone heat treatment, making it an environmentally friendly building material.

2. It has excellent mechanical properties, good water permeability, and is resistant to corrosion and aging.

3. It has strong anti-burial and anti-corrosion performance. The structure is loose and has excellent drainage performance.

4. It has an excellent coefficient of friction and tensile strength, and possesses geotechnical reinforcement performance.

5. It has functions such as isolation, reverse filtration, drainage, protection, stabilization and reinforcement.

6. It can adapt to uneven base layers, resist damage from external forces during construction, and has a small creep.

7. Good overall continuity, light weight and convenient construction.

8. As a permeable material, it has excellent reverse filtration and isolation functions, and strong puncture resistance, thus providing excellent protective performance.

The application and function of HDPE smooth geomembrane

It is mainly applied in anti-seepage lining projects such as landfill, sewage and waste liquid treatment, water conservancy, agriculture, transportation, high-speed rail, tunnels, airports, buildings, and landscapes.

Specification for Construction Plan of HDPE Smooth Geomembrane

During transportation, geotextile membranes should not be dragged or forcibly pulled, and sharp objects should be avoided to prevent punctures.

Extend from the bottom to the higher position. Do not pull too tightly. There should be a 1.50% margin left to allow for local sinking and stretching. Considering the actual situation of this project, the slope is laid in the order from top to bottom.

2. The longitudinal joints of two adjacent pieces should not be on the same horizontal line and should be staggered by more than 1 meter.

3. The longitudinal joints should be at least 1.50 meters away from the dam toe and the bend toe, and should be set on a plane.

4. Slope first, then bottom of the field;

When laying the membrane on the slope, the direction of the membrane extension should be basically parallel to the line of the major slope.

Product specifications

0.3mm to 3mm, width 1m to 8m, length as per customer requirements.