详细内容:

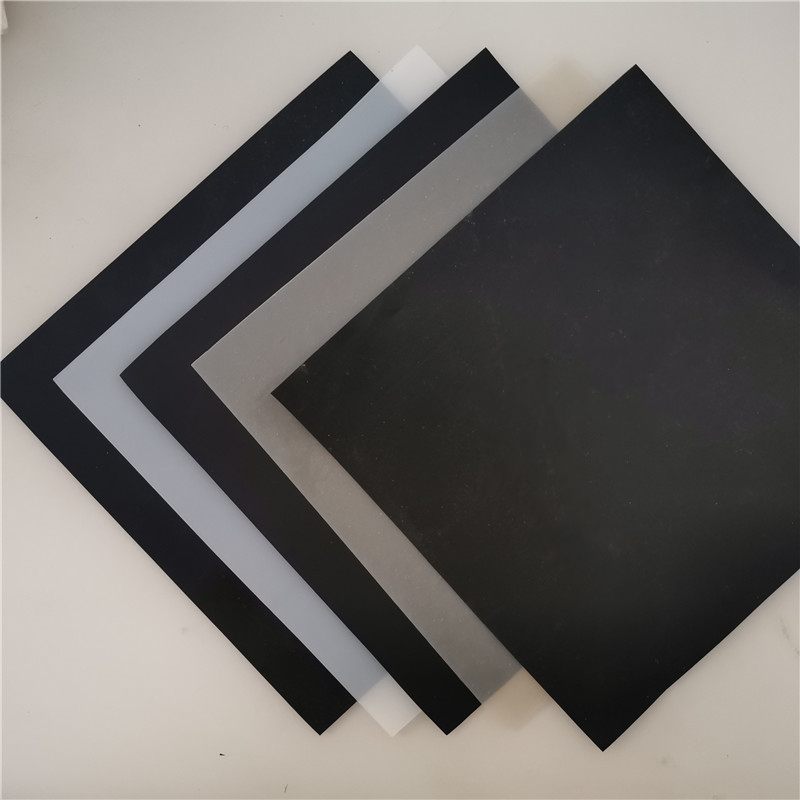

Product Introduction of Aquaculture Anti-seepage Membrane

The aquaculture anti-seepage membrane features high tensile strength, impact resistance, tear resistance, high strength, high hydrostatic pressure resistance, UV resistance and excellent anti-seepage performance. It is particularly applied in fish pond anti-seepage, shrimp pond anti-seepage, loach breeding pond anti-seepage and other projects. Covering the entire fish and shrimp pond or the bottom of the pond with aquaculture anti-seepage membranes can separate the bottom from the water, and has a significant effect on preventing seepage, virus contamination, and microbial erosion in high and low position shrimp ponds. Due to the smooth surface of the aquaculture anti-seepage membrane, it is not only convenient for disinfection and silt removal, but also conducive to preventing the spread of pathogens at the bottom, shortening the time for cleaning the bottom of the shrimp pond and drying the pond.

Construction plan for anti-seepage membranes in aquaculture

A. Personnel unrelated to the laying process are not allowed to enter the construction site.

B. The methods and equipment used for laying must not damage the anti-seepage membrane or the geotextile and base beneath it.

C. Construction workers must wear shoes that do not damage the anti-seepage membrane when working at the construction site.

D. There must be sufficient ballast or anchoring materials to prevent the anti-seepage membrane from being blown up by the wind.

E. The anti-seepage membrane should be laid smoothly, firmly and with as few wrinkles as possible. After laying, it should be promptly ballast or anchored.

F. Choose the laying direction reasonably to minimize the force on the joints as much as possible.

G. Arrange the position of each piece of material reasonably to minimize the number of seams.

H. During the laying process, prevent any factors from damaging the anti-seepage membrane. The laying tools must not cause any damage to the soil anti-seepage membrane.

There shall be no transverse joints on slopes with a gradient greater than 10% within a range of 1.5 meters at the foot of the slope.