详细内容:

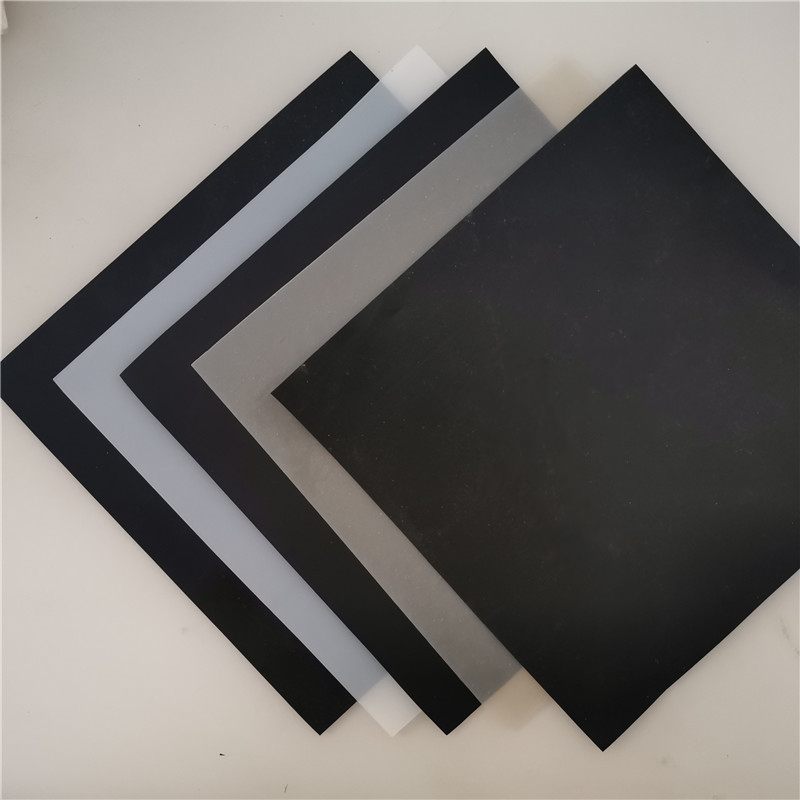

Construction of composite geomembrane: One or both sides of the film are heated by far-infrared rays

in an oven, and the geotextile and geomembrane are pressed together by guide rollers to form a composite

geomembrane. With the improvement of production technology, there is also a casting method for making

composite geomembranes. Its forms include one fabric and one film, two fabrics and one film, two films and

one fabric, etc. Geotextile, as the protective layer of geomembrane, protects the anti-seepage layer from da-

mage. To reduce ultraviolet radiation and enhance anti-aging performance, it is best to lay it by the burial me-

thod.

During construction, the base surface should first be leveled with fine-grained sand or clay, and then the

geomembrane should be laid. Do not stretch the geomembrane too tightly. The parts buried in the soil at both

ends should be in a wavy shape. Finally, cover the laid geomembrane with a transition layer of about 10cm of

fine sand or clay. Build a 20-30cm layer of block stones (or concrete precast blocks) as a protective layer against

erosion. During construction, efforts should be made to avoid direct impact of stones on the geomembrane. It is

best to carry out the construction of the protective layer while laying the membrane. The connection between

the composite geomembrane and the surrounding structures should be anchored with expansion bolts and

steel plate pressure strips. The connection parts should be coated with emulsified asphalt (2mm thick) for bond-

ing to prevent leakage at this location.

Construction matters

(1) It must be used in an embedded manner: the covering thickness should not be less than 30cm.

(2) The renovation of the anti-seepage system should consist of: cushion layer, anti-seepage layer, transition

layer and protective layer.

(3) The soil should be solid to avoid uneven settlement and cracks. The grass and tree roots within the anti-

seepage range should be removed. A protective layer of fine sand or clay with small particle size is laid on the

surface in contact with the membrane.

(4) When laying the geomembrane, do not pull it too tightly. It is better for the parts buried in the soil at both

ends to be in a wavy shape. Especially when anchoring it with rigid materials, a certain amount of expansion

allowance should be left.

(5) During construction, it is necessary to avoid direct impact of stones or heavy objects on the geomembrane.

It is best to lay the membrane and cover it with a protective layer while constructing.