详细内容:

Geomembrane is a kind of anti-seepage material, which is often used in many environmental

protection and anti-seepage projects. Due to its good anti-seepage effect and relatively low cost,

it is also widely used in the aquaculture industry and lotus root planting industry. Many people are

confused about the choice of membrane materials. So the author will tell everyone how people

usually choose between these two applications.

Is the first choice of anti-seepage geotextile membrane used for lotus pond anti-seepage and fish

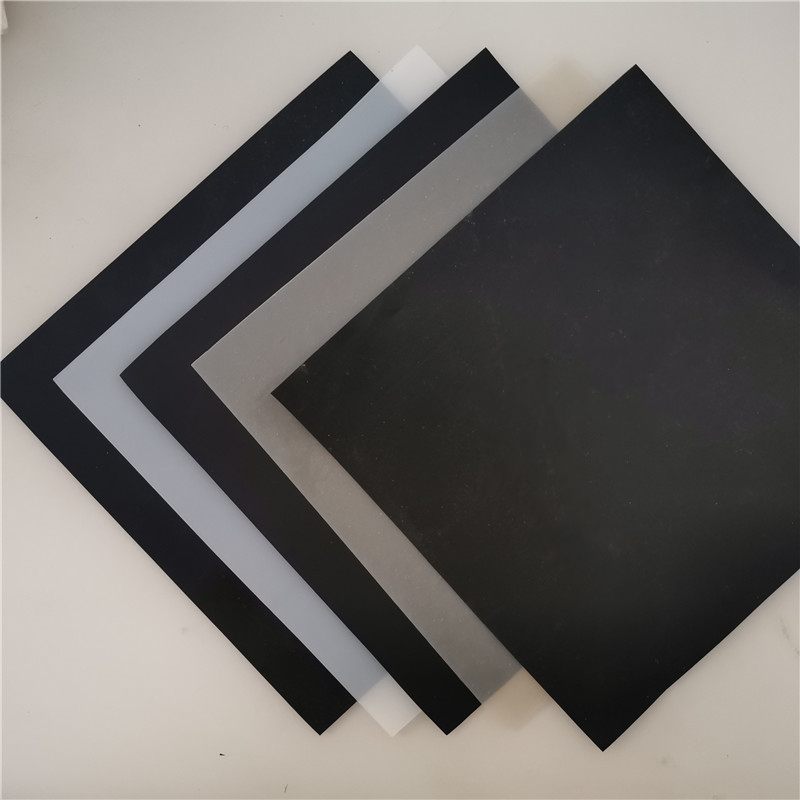

pond anti-seepage the same type of geotextile membrane? Professionally speaking, there are two types

of anti-seepage membranes in these two fields: one is composite geomembrane and the other is geo-

membrane. "Two (two) fabrics and one membrane" means that geotextile and geomembrane are ther-

mally compounded together, which also has a very good anti-seepage effect and features such as rein-

forced anti-seepage and acid and alkali resistance and corrosion resistance. The specifications of geo-

textile and geomembrane can be produced according to customer requirements, and there are also

many thickness specifications of geomembrane, from It can be produced from 0.2mm to 2.0mm.

In terms of aquaculture, these two types of aquaculture anti-seepage membranes each have their

own advantages. The main function of both is to prevent seepage. If we only consider the aspect of pr-

eventing seepage, their effects are the same. Apart from the anti-seepage function, other functions

determine their application sites. For fish pond anti-seepage, people more often choose geotextile

membranes, also known as fish pond anti-seepage membranes. Its structure is a single-layer high-

density geotextile membrane, without double-sided ones Why choose non-woven fabric? Because

non-woven fabric is made of recycled materials. The toxic substances that have not been completely

volatilized in non-woven fabric can cause serious harm to fish, leading to large-scale diseases or

casualties. Therefore, composite geomembrane is rarely used in fish pond aquaculture. In addition,

the smooth surface of the geomembrane can effectively prevent fish from escaping during the rainy

season, especially fish that are good at escaping such as lobsters, crabs, soft-shelled turtles, loaches

and eels. Overall, smooth geomembranes are commonly used in fish pond anti-seepage or shrimp

pond anti-seepage applications. It is recommended to use geotextile membranes produced from

virgin materials. This way, they will not release harmful substances, reduce fish deaths and injuries,

and thereby increase income.

"Requirement" : Geotextile serves as the protective layer for geomembrane to prevent damage to

the anti-seepage layer. To reduce ultraviolet radiation and enhance anti-aging performance, it is best

to lay it by the burial method. During construction, first use fine sand or clay with smaller particle size

to level the base surface, and then lay it. When laying, do not stretch it too tightly. The parts buried in

the soil at both ends should be in a wavy shape. Finally, on the two layers of fabric and one layer of film

laid, spread a transition layer of about 10cm with fine sand or clay. Build a 20-30cm layer of block stones

(or concrete precast blocks) as a protective layer against erosion. During construction, efforts should be

made to avoid direct impact of stones on it. It is best to carry out the construction of the protective layer

while laying the film.

The connection between the two layers of fabric and one layer of film and the surrounding structures

should be anchored with expansion bolts and steel plate pressure strips. The connection parts should be

coated with emulsified asphalt (2mm thick) for bonding to prevent leakage at this location. Construction

joint treatment is a crucial process that directly affects the anti-seepage effect. The common joint methode

include :① Lap joint: The lap width should be greater than 15cm; ② Hot welding: It is suitable for slightly

thicker geomembrane base materials, and the lap width of the weld seam should not be less than 5CM.

(Adhesive bonding is not recommended. It is prone to delamination after long-term water immersion and

has poor anti-seepage effect.) Finally, scatter some grass seeds on the slope protection to carry out turf

slope protection to prevent rain erosion.