详细内容:

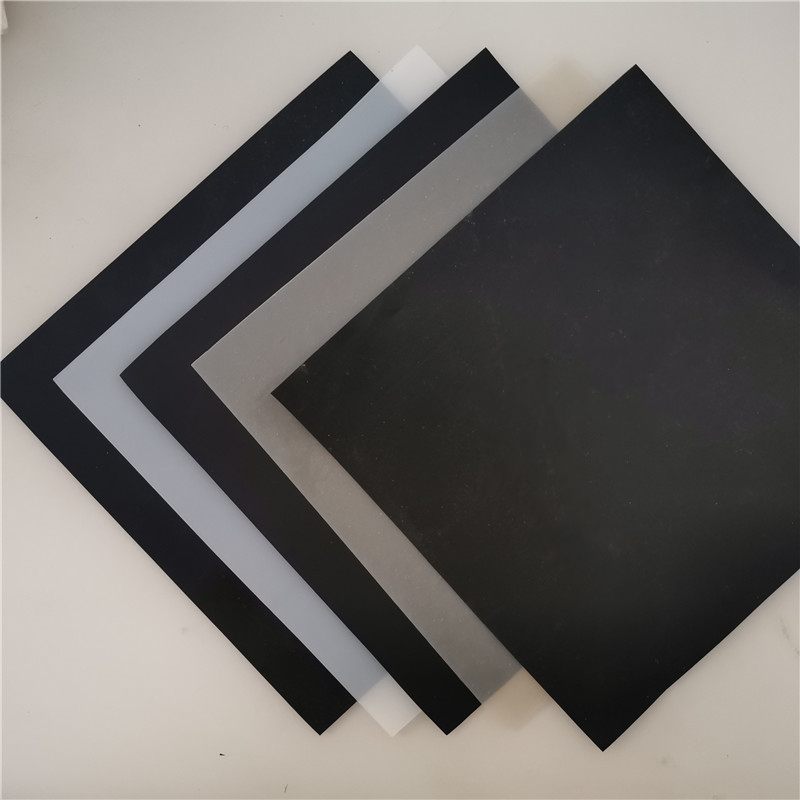

EVA waterproof board is a new type of synthetic polymer waterproof membrane with excellent waterproof

performance, which is made by compounding synthetic polymer EVA composite sheet, high polymer and mod-

ified high-quality asphalt as the base material. EVA waterproof board combines the waterproof performance ofboth high-molecular waterproof membranes and self-adhesive waterproof membranes. With one layer of mem-

brane, it provides two layers of protection, significantly enhancing the waterproof effect of the waterproof layer.

It can be applied in low-temperature and humid environments. It features excellent bonding and sealing perfor-

mance, puncture resistance and self-healing properties, high elongation, and is non-toxic and odorless, meeting

environmental protection requirements.

Product features of EVA waterproof board

EVA waterproof boards feature excellent impermeability, high puncture resistance, high barrier properties,

low-temperature flexibility, superior physical performance, aging resistance, resistance to chemical erosion, and

are easy to weld. They can be installed at extremely low on-site temperatures.

The application scope of EVA waterproof board

Tunnels, subways, water conservancy projects, highways, and drainage projects; Gate and dam protection

projects; Waterproofing and seepage prevention for buildings; Urban landfill; Port construction Fish ponds, salt

production, and pipe gushing prevention; Industrial and domestic water storage, golf courses, swimming pools etc.

The performance differences among EVA waterproof boards, ECB waterproof boards and PE waterproof boards

At present, the polymer rolls commonly used in waterproofing and anti-seepage projects mainly include several

categories such as PVC (polyvinyl chloride), ECB (ethylene-vinyl acetate and asphalt copolymer), EVA (ethylene-vinyl

acetate copolymer), LDPE (low-density polyethylene) and HDPE (high-density polyethylene). Among them, HDPE has

high strength but high hardness, and is rarely used in tunnel waterproofing. PVC has relatively poor performance

and is no longer used in tunnel waterproofing, so this standard does not impose requirements on them. EVA type

rolls, the accurate name should be EVA modified PE rolls. They are mainly made of EVA modified PE, with the EVA

content generally ranging from 20% to 50%, but they are still conventionally called EVA rolls. After EVA is modified

into PE, both the flexibility and elongation of the sheet material will be significantly improved.