详细内容:

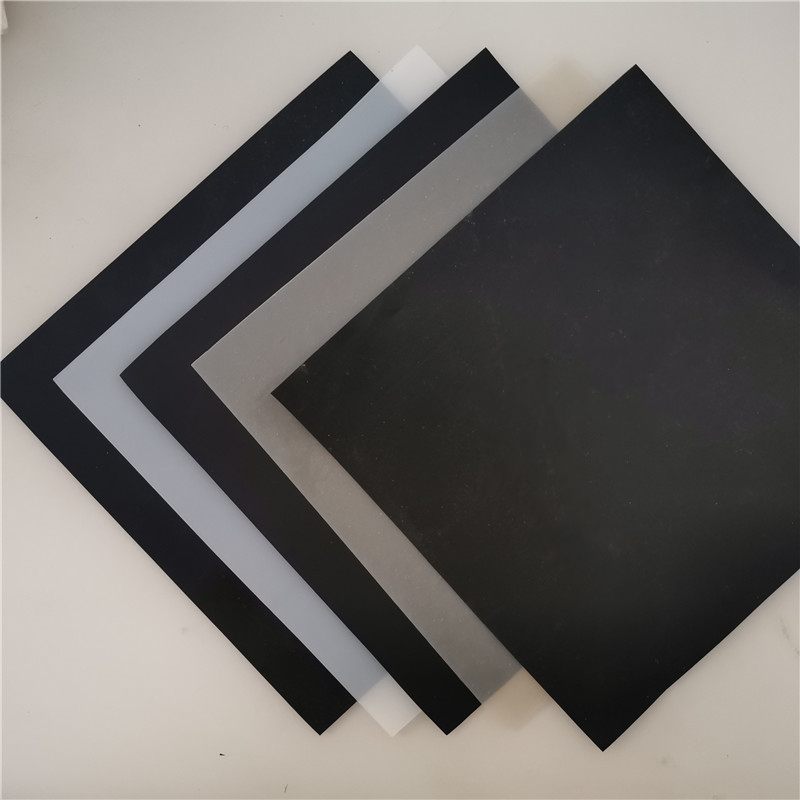

The general sequence for the construction of geomembranes is as follows: understanding the project,

site survey, equipment supply, construction methods, on-site inspection, etc. HDPE geomembrane can be

constructed under certain ambient temperatures. Due to its own good cold resistance, the ambient tempe-

rature for its application is generally a high temperature of 110 degrees Celsius and a low temperature of

minus 70 degrees Celsius. So, even in the cold winter, there is no need to worry that it will affect the con-

struction of geomembrane.

When carrying out the construction of geomembrane in winter, the key point to note is that the seams

must be properly handled. Due to the relatively dry winter, during construction, when HDPE geomembrane

and anti-seepage geomembrane are welded together, the strength and anti-seepage and waterproof cap-

abilities of the geomembrane cannot be well guaranteed due to the influence of factors such as the thickn-

ess of the membrane, temperature, wind force, humidity, voltage and flatness. Therefore, doing a good job

in the basic work such as seams can also ensure that the geomembrane has good anti-seepage and water-

proof performance.

When installing HDPE geomembrane, the geomembrane should be tightened when the ambient tem-

perature is low, loosened when the temperature is high, and the wind force should be below level 4. When

the temperature is too low, construction is generally not allowed in strong winds of force 4 or above, or in

rainy and snowy weather. In strong wind weather, when the wind force affects the construction of geomem-

brane, the HDPE geomembrane to be welded should be firmly pressed with anti-aging woven bags to pr-

event problems.

In winter, composite geomembrane becomes very brittle. Therefore, to prevent the composite geo-

membrane from breaking due to passivity in winter and causing leakage, it is important to remember not

to lay the composite geomembrane or carry out related operations in winter. Secondly, it is necessary to

prevent the large settlement of the dam body from causing the front dam slope to settle and deform dur-

ing the winter operation period of the reservoir, resulting in the brittle fracture of the membrane material.

Therefore, the dam body should be compacted layer by layer in accordance with the design standards.

After each layer is compacted, water should be poured for soaking to ensure the dam body is filled tightly.