产品介绍:

![1602664196207076.jpg 1-200316202643[1].jpg](/static/upload/image/20201014/1602664196207076.jpg)

Product Introduction

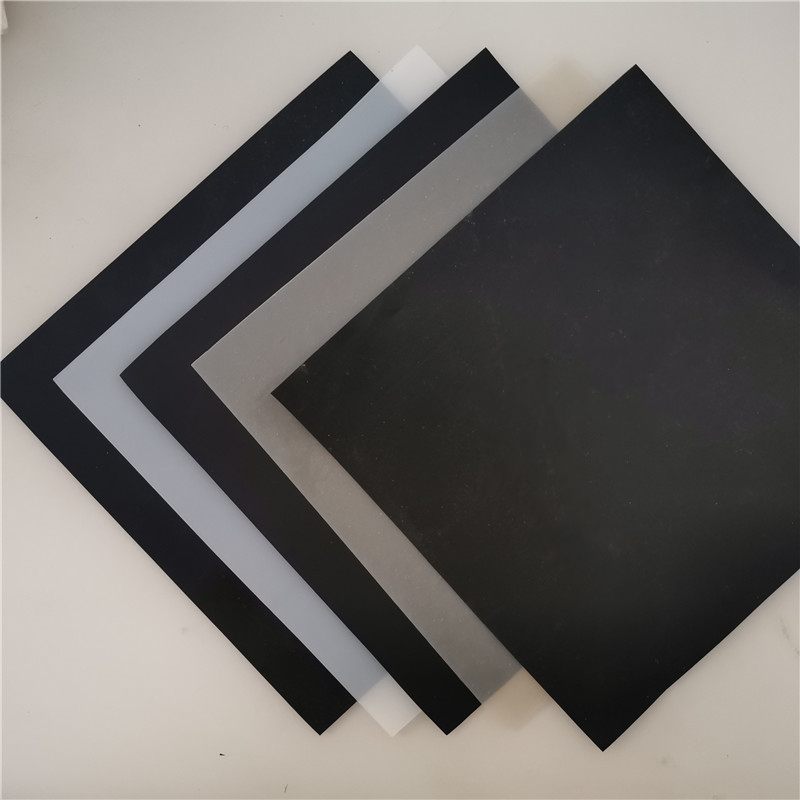

HDPE membrane is also known as high-density Polyethylene membrane, HDPE geotextile membrane, and HDPE

anti-seepage membrane. Its English name is "High Density Polyethylene Impermeable membrane", and it is simply

called "HDPE membrane". HDPE is a thermoplastic resin with high crystallinity and non-polarity. The original state of

HDPE appears milky white and is semi-transparent to a certain extent in thin sections. HDPE has excellent anti-corrosion

performance, electrical performance, moisture-proof performance, anti-seepage performance and high tensile strength.

Therefore, it is very suitable for engineering anti-seepage, aquaculture anti-seepage, oil tank anti-seepage, basement

anti-seepage, artificial lake anti-seepage and other fields.

Performance features

1. High anti-seepage coefficient - The anti-seepage membrane has an anti-seepage effect that ordinary waterproof

materials cannot compare with. HDPE anti-seepage membrane has high tensile strength and mechanical properties.

Its excellent elasticity and deformation capacity make it very suitable for expanding or contracting base surfaces,

effectively overcoming the uneven settlement of the base surface. The water vapor permeability coefficient K is <=

1.0*10-13 GCM /ccm2spa.

2. Aging resistance - The anti-seepage membrane has excellent anti-aging, anti-ultraviolet and anti-decomposition

capabilities. It can be used exposed and has a material service life of 50 to 70 years, providing a good material

guarantee for environmental anti-seepage.

3. High mechanical strength - The anti-seepage membrane has excellent mechanical strength, with a tensile strength

at break of 28MPa and an elongation at break of 700%.

4. Resistance to plant roots - HDPE anti-seepage membrane has excellent puncture resistance and can withstand the

root systems of most plants.

5. Chemical Stability - Anti-seepage membranes have excellent chemical stability and are widely used in sewage

treatment, chemical reaction tanks, and landfill sites. Resistant to high and low temperatures, asphalt, oil and tar, as

well as over 80 kinds of strong acid and alkali chemical media such as acids, alkalis and salts.

6. Fast construction speed - The anti-seepage membrane has high flexibility, with various specifications and laying

forms to meet the anti-seepage requirements of different projects. It is welded by hot melt, with high weld strength,

and is convenient, fast and healthy to construct.

7. Low cost and high efficiency - HDPE anti-seepage membrane adopts new technology to enhance the anti-seepage

effect, but the production process is more scientific and rapid. Therefore, the product cost is actually lower than that

of traditional waterproof materials. According to actual calculations, general projects using HDPE anti-seepage

membrane can save about 50% of the cost.

8. Environmentally friendly and non-toxic - The materials used in the anti-seepage membrane are all non-toxic and

environmentally friendly. The anti-seepage principle is a common physical change, which does not produce any harmful

substances. It is an ideal choice for environmental protection, aquaculture, and drinking water pools.

Function and application

It is mainly applied in anti-seepage lining projects such as landfill, sewage and waste liquid treatment, water conservancy,

agriculture, transportation, high-speed rail, tunnels, airports, buildings, and landscapes.

Product specifications

0.3mm to 3mm; It is generally 1 to 8 meters, and can reach up to 13 meters.