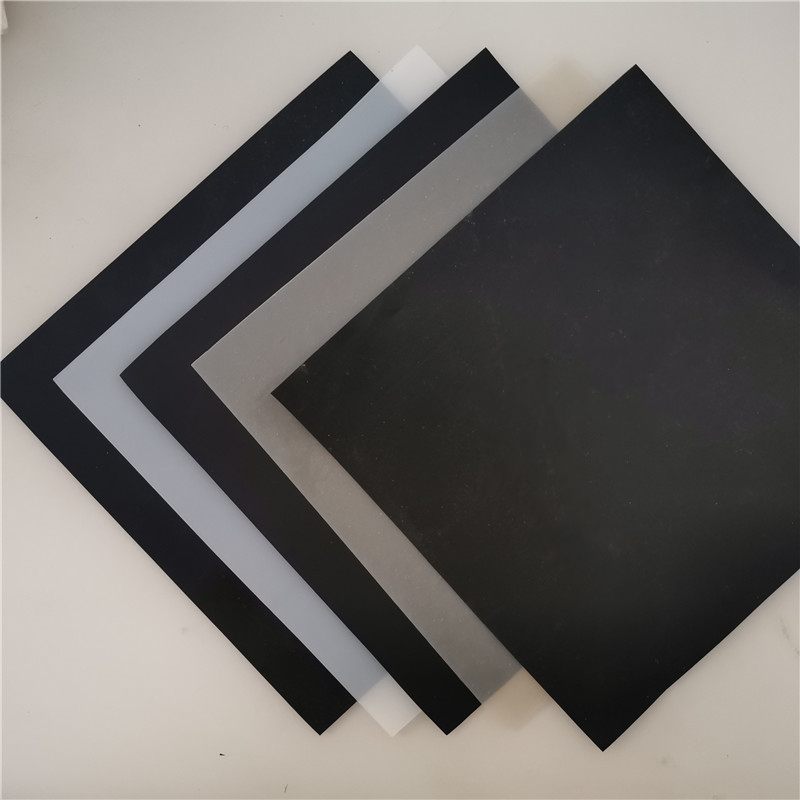

产品介绍:

![1602752337112749.jpg 201704131227056673[1].jpg](/static/upload/image/20201015/1602752337112749.jpg)

Geomembrane laying

1.Before laying the geomembrane, there should be corresponding qualified acceptance certificates

of the civil engineering works.

2.Before cutting the geomembrane, its relevant dimensions should be accurately measured and then

cut according to the actual size. Generally, it is not advisable to cut according to the dimensions shown

in the drawing. Each piece should be numbered and the details should be recorded in a dedicated form.

3.When laying geomembrane, efforts should be made to minimize the number of welds. Under the

premise of ensuring quality, raw materials should be saved as much as possible. It is also easy to

ensure quality at the same time.

4. The lap width of the seams between membranes is generally no less than 10cm. Usually, the weld

seams are arranged parallel to the maximum slope, that is, along the slope direction.

5. Generally, at corners and irregular sections, the length of the joints should be shortened as much

as possible. Except for special requirements, welds should not be set within 1.5 meters from the top

slope or stress concentration areas on slopes with a gradient greater than 1:6.

6. During the laying of geomembrane, artificial wrinkles should be avoided. When the temperature is

low, it should be stretched as tightly as possible and laid flat.

After the geotextile membrane is laid, walking on the membrane surface and moving tools should be

minimized as much as possible. Any objects that could cause damage to the anti-seepage membrane

should not be placed on the membrane or carried while walking on it to avoid accidental damage to

the membrane.

The main functions of geomembrane

It integrates the functions of anti-seepage and drainage, and also has the functions of isolation and

reinforcement.

2. It features high composite strength, large peel strength and high puncture resistance.

3. It has strong drainage capacity, a large friction coefficient and a small linear expansion coefficient.

4. Good aging resistance, wide range of environmental temperature adaptability, and stable quality.

Geomembrane engineering application

The warp knitted composite reinforced waterproof geotextile has excellent water resistance, durability

and protection. It can be widely used in railway, highway, sports venues, DAMS, hydraulic structures,

tunnels, coastal tidal flats, reclamation, environmental protection and other projects.