详细内容:

Construction of bentonite waterproof blanket

(1) Foundation requirements before construction

1. The base surface can be of various types, such as walls, slopes, rocks, etc.

2. The base surface should be basically dry and must not have obvious water accumulation.

3. The radius of the bottom layer and the rounded corners should be no less than 30cm.

4. The backfill soil and the ground must not contain any polluting or harmful substances. If any, they must be thoroughly cleaned up.

5. The compaction degree of the base layer should be over 85%, and the compaction density should be uniform. Insufficient density may cause foundation settlement and affect the long-term effect.

6. Remove all debris such as stones, tree roots, iron wires (nails), etc. from the base layer thoroughly.

7. If there are any concave holes on the base layer, they must be repaired and filled with bentonite mortar or high-grade mixture.

8. Excavate the anchor trench as per the design requirements;

9. The construction of bentonite waterproof blanket should be carried out after the foundation and working layer works have been accepted as qualified.

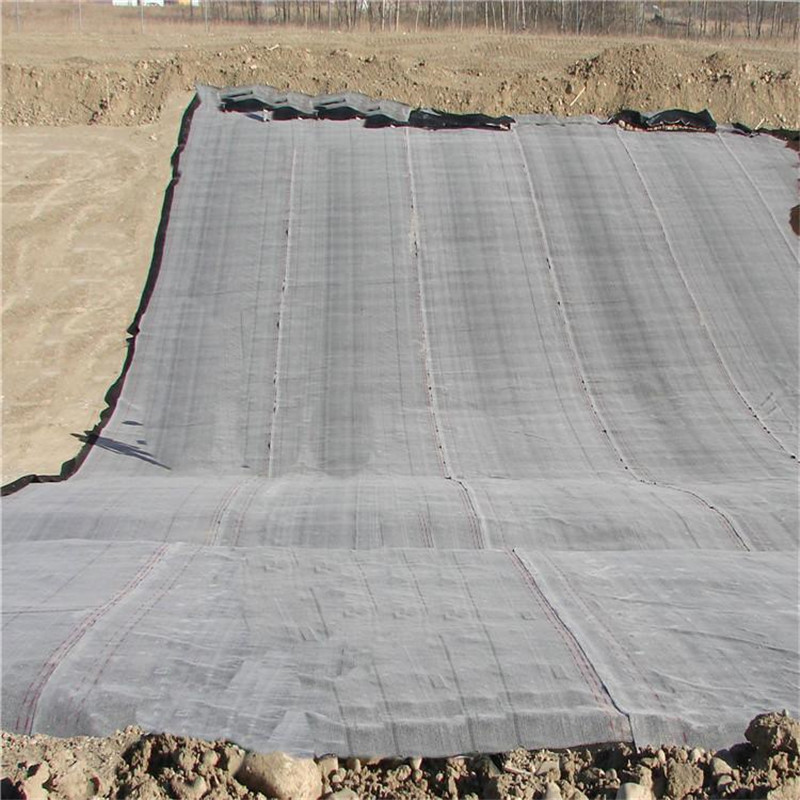

(II) Construction and Laying

1. Formulate a detailed construction plan before construction;

2. The laying of bentonite waterproof blankets should avoid being carried out when there is water or on rainy days. Unlaid waterproof blankets should also be stored away from water, and water must not seep into the waterproof blankets.

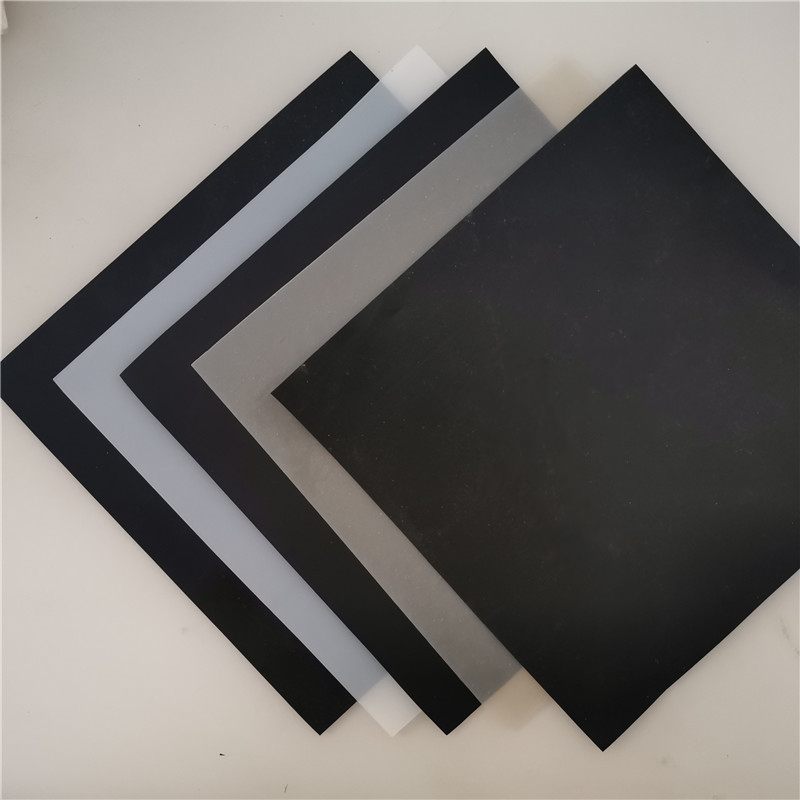

3. Before laying the bentonite waterproof blanket, confirm the front and back sides of the laying according to the design requirements or the project conditions. Generally, the woven geotextile (black side) is laid down and the non-woven fabric (white side) is laid up. If necessary, it can also be laid in reverse.

4. When laying, each roll of waterproof blanket should be positioned as per the design requirements by a crane or forklift, and then spread out flat by hand.

5. When laying GCL in water feature projects, streams and ditches, the laying sequence should first consider the water flow, that is, the waterproof blanket upstream of the water flow should be placed on top of the waterproof blanket downstream.

6. When laying the bottom surface, it should be overlapped parallel and not joined parallel. The fabric surface should not be stretched too tightly or wrinkled. It should be slightly relaxed and closely attached to the ground.

7. When laying on a slope, it should be laid along the top and bottom of the slope and overlapped parallel.

8. The lap width (where two layers overlap) should be at least 300mm. Between the overlapping layers, evenly sprinkle bentonite powder or evenly apply bentonite mortar.

9. The laying progress should be coordinated with the backfilling progress. After laying, on the same day, more than 200mm of soil, sand or grade mixture should be backfilled as per the design requirements and covered and compacted.

When encountering through parts during laying, a double-layer waterproof blanket should be laid within 500mm around the through object. At the contact point between the waterproof blanket and the through object, the upper and lower layers of the waterproof blanket should form a bell mouth, and the contact line distance from the through object should be at least 50mm. The bevel length of the waterproof blanket should be about 100mm. The gap between the two blankets should be filled with bentonite powder (or bentonite mortar). The junction between the small pieces of waterproof blanket on the upper layer and the entire waterproof blanket on the lower layer should be bonded with tape and then fixed.

11. During the laying process, if the waterproof blanket is damaged, it should be covered with a waterproof blanket larger than 300mm around the damaged gap before being fixed.

12. When laying, if it rains, it should be quickly covered with plastic film material or rainproof material. When the rain is heavy and the bentonite expands by more than 300%, it should be re-laid.

13. When laying, it is strictly forbidden to place open flames or cigarette butts on any side of the waterproof blanket.

(3) Several anti-seepage construction schemes for different sites

1. Anti-seepage construction plan for vertical concrete walls:

When constructing on vertical concrete walls, the top of the waterproof blanket should extend 20 to 30cm beyond the horizontal plane and be fixed at the top with 4# flat steel and steel nails. On the outside of the waterproof blanket, a clear brick wall should be built for protection. Finally, backfill 20 to 30cm of soil at the bottom.

2. Anti-seepage construction plan for vertical hard revetments:

When constructing a waterproof blanket on a vertical hard revetment, first backfill the soil at a slope of 1:3, and then lay the waterproof blanket on the backfill soil. The top of the waterproof blanket should extend 20 to 30cm above the horizontal plane. The upper opening is compacted and fixed to the top of the hard revetment with the original stones. Finally, backfill 20 to 30cm of soil above the waterproof blanket.

3. Anti-seepage construction plan for walls built with rubble:

When GCL is used for the construction of a wall built with rubble, first, the soil should be backfilled at a slope of 1:3 to form a relatively flat slope on the construction surface, and then a waterproof blanket should be laid on the backfilled slope. The top of the waterproof blanket should extend 20 to 30cm beyond the horizontal plane, and the top of the waterproof blanket should be compacted and fixed to the top of the rock pile with the original stones. Finally, backfill 20 to 30cm of soil above the waterproof blanket.

Construction Precautions

The waterproof blanket must be overlapped from top to bottom, and the overlap length should be greater than 100mm. As shown in A.

2. After the GCL is overlapped, steel nails should be used to fix the overlapped area and its upper end. As shown in A.

3. The radius of the bottom layer and the rounded corners should be no less than 30cm.

4. The compaction degree of the backfill soil in contact with the waterproof blanket must reach over 85%.

(4) Fixation of the waterproof blanket after laying

1. Fixation at the lap joints: If necessary, the lap joints should be fixed as per the design requirements (generally, one-inch steel nails are used at intervals of 1500mm).

2. When the slope ratio of the slope surface is no more than 1:3, top fixation should be adopted. Anchor trenches can be excavated around the top of the slope, with a depth and width of approximately 450-500mm. The waterproof blanket should be buried at the bottom of the trench and then covered and compacted with soil, sand, gravel or grade materials.

When the slope ratio of the slope surface is greater than 1:3, anchor trenches must be set up around it for the fixation of the waterproof blanket. The anchor trenches at the bottom of the slope and on the slope surface should be poured with concrete and steel wire mesh (4# steel wire mesh) on the laid waterproof blanket. The anchor trenches at the top of the slope can be covered and compacted with soil, sand or grade materials.

When the slope of an artificial lake exceeds 15 degrees, the slope part can be compacted with 10 centimeters of thick concrete. When large pebbles are laid on the slope section, the thickness of the concrete can be appropriately reduced, but the total compaction thickness should be greater than 10 centimeters.

5. For the joints of parts with strange and irregular shapes, in addition to reinforcing them with bentonite powder, a slurry of bentonite should also be applied to the surface of the joints for reinforcement.

6. If the laid waterproof blanket is damaged, it can be covered with a complete waterproof blanket block that is about 30 centimeters wider according to the size of the damage and fixed with cement nails.

7. Both ends of the terminal parts should be fixed by anchor rods.

The anchor bolt part of the GCL should be fixed at the uppermost part of the horizontal plane and firmly fixed.

When the anchor rods are submerged in water and have a large inclination, double-layer GCL should be used for construction.

The width of the anchor bolt part should be 15cm and the depth should be over 0.6 meters. After folding the waterproof blanket at the bottom of the anchor bolt, it should be compacted with backfill soil to over 90%.

(V) Other precautions when laying bentonite waterproof blankets

In case of water accumulation or water seeping out from underground, point the well and start pumping water immediately. Before the water is drained after the laying is completed, there should be no seepage or accumulated water soaking the bentonite waterproof blanket. For specific construction methods and technical specifications, please refer to "Industry Standard of the People's Republic of China: Technical Specification for Application of Geosynthetics in Water Conservancy and Hydropower Engineering (SL/T225-98)".

2. In case of rain or snow, if the expansion of the bentonite waterproof blanket exceeds 300%, it must be cut and re-laid.

3. In case of rain or snow, it is necessary to quickly backfill the grade materials or cover them with a waterproof blanket made of PE film for protection.

4. All fire sources must be kept away from the bentonite waterproof blanket.

When there are tears or gaps in the bentonite waterproof blanket, a piece of bentonite cloth should be placed over the gap, which should be more than 20 centimeters larger than the area around the gap, and fixed with steel nails.

After the bentonite waterproof blanket is laid, if there is a leakage that cannot be approached, the leak will be repaired by injecting resin or chemical catalyst grouting. Before the repair, complete information will be provided, explaining the materials and steps for the repair. Only after approval by the engineer will the repair be carried out.

(6) Water drainage requirements after the completion of the bentonite waterproof blanket laying

1. Clean up the construction site again and leave no debris on it.

2. For the first water release, clean water should be used to activate bentonite for at least 48 hours.

3. When releasing water for the first time, no harmful water quality or sewage should enter.

(7) Inspection of the construction quality of waterproof blankets

Bentonite waterproof blanket needs to be backfilled with soil immediately during construction. Therefore, after each process is completed, it must be inspected and accepted as qualified by quality inspection or supervision personnel before proceeding to the next process. Generally, it is required to:

1. Check whether the lap joint, laying and fixation comply with the above regulations.

2. Whether the damaged and repaired parts comply with the above regulations.

3. Whether the construction at the connection point complies with the requirements of the above regulations.