详细内容:

Construction plan for geomembrane in landfill sites

First of all, make thorough preparations. Clean, compact and level the surface of the base layer to be laid. Then, take materials from the ground. Use an excavator to fill the soil on the surface of the base layer. The filled soil layer should be no less than 30 centimeters thick. If there is no yellow soil, yellow sand or fine sand can be used as substitutes. After filling the soil layer or sand layer and compacting the soil protection layer, prepare for the next step of work: dig underground water drainage channels and distribute drainage pipes.

Secondly, the soil protection base layer that has been laid should be leveled and compacted. The surface should be smooth and flat, without any protruding stones more than 2cm or obvious small pits. After checking for no issues, let the bentonite waterproof blanket relax naturally and lay it flat on the soil protective layer, with the non-woven fabric side facing down and the woven fabric side facing up. Note: The construction of bentonite waterproof blanket should be carried out in rainy or snowy weather. In case of rain or snow during construction, it should be covered with plastic film to prevent the bentonite in the waterproof blanket from expanding upon contact with water. The lap joint of the bentonite waterproof blanket should be no less than 20 centimeters. Evenly sprinkle bentonite lap powder on the lap edge, spray water to make it adhere, then press it tightly and keep it flat. After the laying is completed, check if the waterproof blanket is damaged or has any holes and repair them in time to prepare for the next step of work.

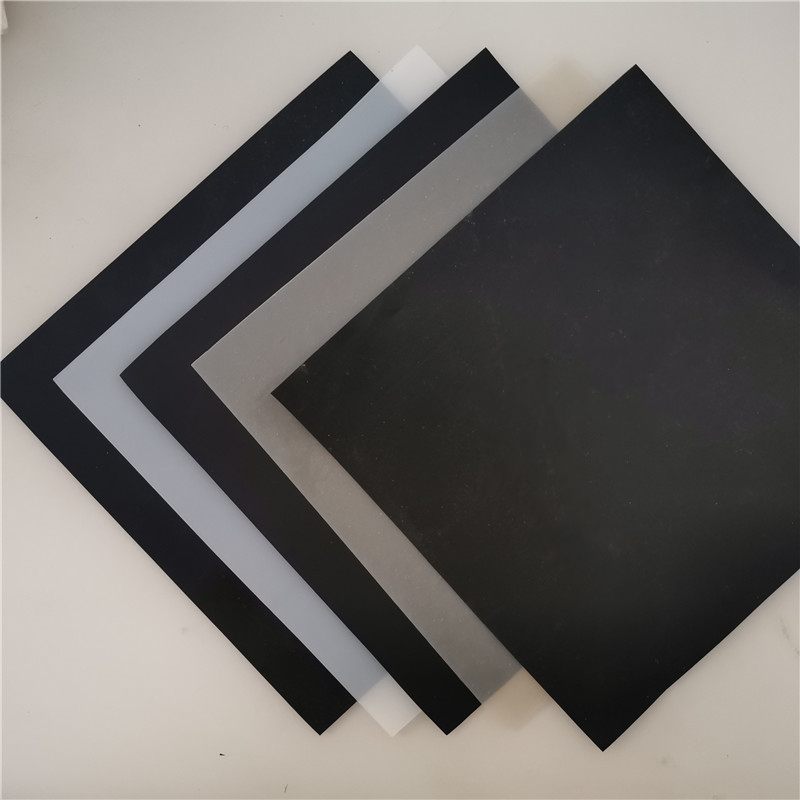

Then comes the laying of HDPE high-density polyethylene geomembrane. Europe began to use HDPE high-density polyethylene geomembrane, also known as HDPE anti-seepage geomembrane or anti-seepage membrane, in the anti-seepage projects of landfill sites as early as the 1980s. With the increasing emphasis on the ecological environment in our country and the growing public awareness, anti-seepage membranes have been widely applied in landfill treatment. Lay the HDPE anti-seepage membrane on the bentonite waterproof blanket, stretch it flat without any large air bubbles, and press it flat to prevent heavy machinery such as excavators from rolling over or turning and walking on the laid anti-seepage membrane. The overlapping edge of the anti-seepage membrane should be no less than ten centimeters, and the edge should be kept clean without any debris or stones. Then prepare for welding. Before welding, take two pieces of geomembrane about one meter in length for a test weld, adjust the reasonable temperature of the welding machine, and then have professional welders do the welding. Welding should be carried out simultaneously with the laying of the anti-seepage membrane until it is completed. Note: During the laying process of the geomembrane, the excavator should evenly and slowly weigh the soil on the side to cover the geomembrane. The welding and filling should be carried out simultaneously to prevent the geomembrane from being damaged by human activities. The protective soil layer on the cover geomembrane should be no less than 30 centimeters thick to prevent plant roots from piercing the geomembrane, and then the soil layer should be compacted.

After the geomembrane is laid, the long-fiber nonwoven geotextile will be laid by manual rolling. The fabric surface will be stretched and leveled, with the lap edge not less than ten centimeters. After laying, check whether there is any damage or holes on the surface of the long-fiber geotextile. It should be repaired and ready for the next step of work. Then, cover the soil layer on the long-fiber geotextile, ensuring that the soil layer is no less than 30 centimeters thick, and compact and level the soil layer. Then, lay short-fiber geotextile on the compacted protective soil layer, roll it out manually, stretch and level the fabric surface, and the lap edge should not be less than ten centimeters. After laying, check whether the geotextile is intact and deal with it in time.