详细内容:

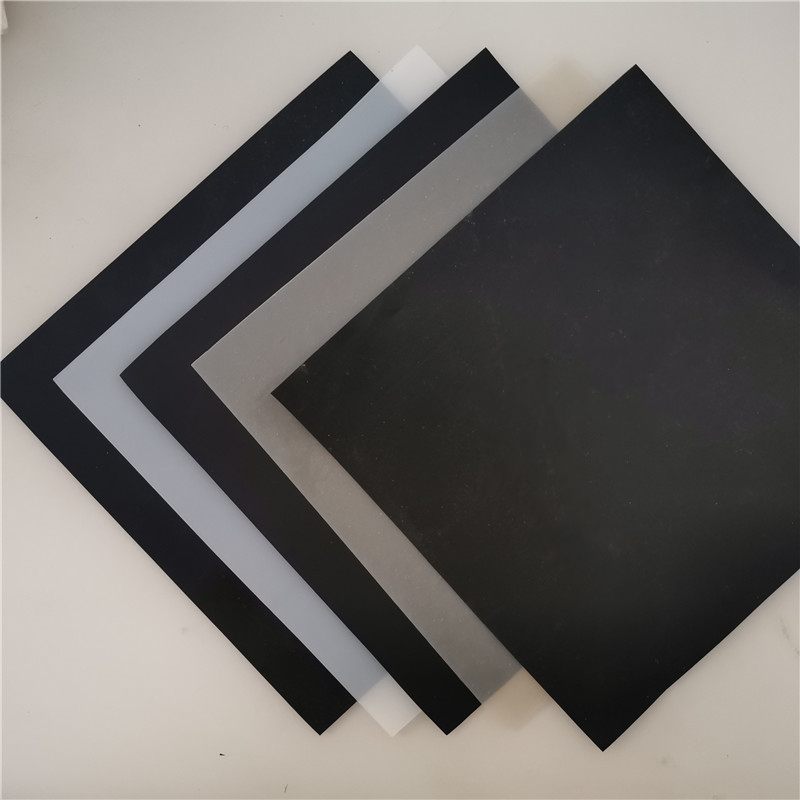

HDPE smooth geomembrane

Function and application

Environmental protection projects: landfill sites, sewage treatment plants, chemical wastewater ponds, power plant regulating ponds, industrial/medical waste landfills

Anti-seepage for ash and slag yards and evaporation ponds.

Petrochemical industry: Oil storage tanks in petrochemical refineries, sludge tanks in oil Wells, chemical reaction tanks, sedimentation tanks, and bottom linings of tailings DAMS, 2

The secondary liner has anti-seepage properties.

Chemical and mining industry: Anti-seepage for the bottom lining of ash and slag yards, red mud piles, heap leaching tanks, dissolution tanks, sedimentation tanks, and tailings DAMS.

Aquaculture: Inner lining of aquaculture ponds, fish ponds and shrimp ponds, anti-seepage for sea cucumber rings, slope protection, etc.

Construction projects: subway, underground garage, roof garden, sewage pipe, and water trap culvert anti-seepage.

Agriculture, forestry and animal husbandry: Anti-seepage for reservoirs, water storage tanks, drinking water tanks and irrigation systems.

Salt chemical industry: Anti-seepage for salt field crystallization pools, brine pool bitter covers, salt films, etc.

Construction technology

After the geotextile membrane is laid, walking on the membrane surface and moving tools should be minimized as much as possible. Any objects that can cause damage to the geotextile membrane should not be placed on the membrane or carried while walking on it to avoid accidental damage to the membrane. When laying geosynthetic membranes, efforts should be made to minimize the number of welds. Under the premise of ensuring welding quality, raw materials should be saved as much as possible. The lap width of the seams between membranes is generally no less than 10cm. Usually, the weld seams are arranged parallel to the larger slope, that is, along the slope direction.