详细内容:

![1602838863643095.jpg 1-201015133IE95[1].jpg](/static/upload/image/20201016/1602838863643095.jpg)

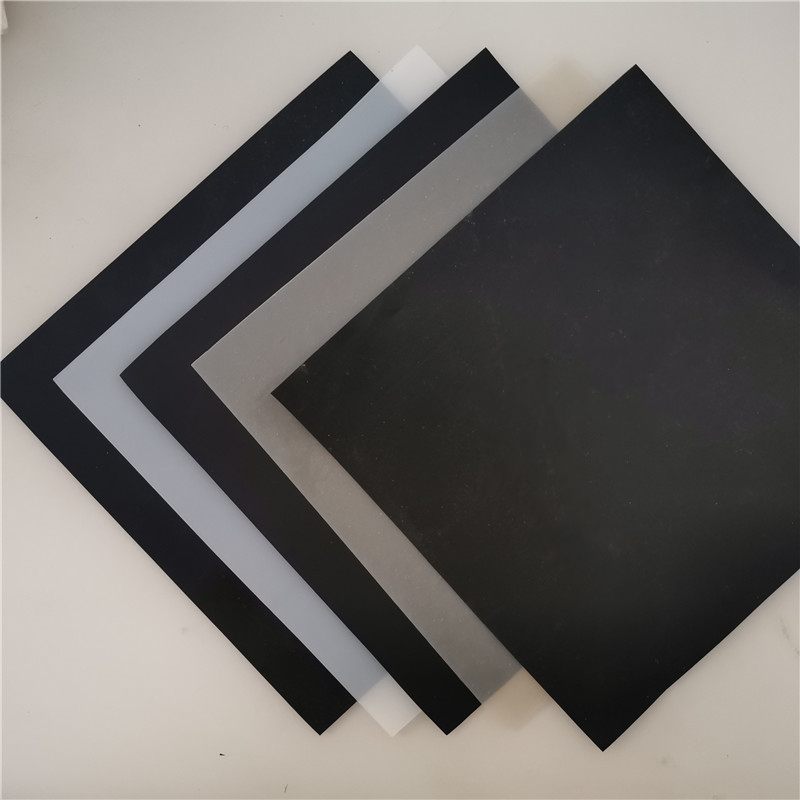

Geosynthetic materials such as geomembranes, geotextiles, and geotextile composite bentonite liners

are widely used in modern sanitary landfills, highway projects, and water conservancy and water transport

projects. Especially, compared with compacted clay lining and single-layer film lining, bentonite waterproof

blanket composite lining has the advantages of good hydraulic anti-seepage performance and easy guaran-

tee of construction quality.

The stress-displacement curves of the smooth geomembrane/geotextile interface, the rough geom-

embrane/geotextile interface and the rough geomembrane/bentonite waterproof blanket interface mostly

show obvious peak strength and post-peak softening. The shear strength of rough geotextile membranes

is generally higher than that of smooth geotextile membranes. The extrusion of hydrated bentonite will

weaken the shear strength at the interface of the bentonite waterproof blanket.

Most studies on the shear strength characteristics of the interface between geomembranes, geotextiles

and bentonite waterproof blankets have been conducted independently, and the corresponding mechanisms

have been analyzed. The shear test of the geomembrane/geotextile interface shows that the peak shear str-

ength at the rough geomembrane and non-woven fabric interface is significantly higher than that at the smooth

geomembrane and non-woven fabric interface, and the horizontal displacement corresponding to the peak

stress is also larger. The reasons for the softening of the interface between geomembrane and geotextile include

the fibers on the surface of non-woven fabric being pulled out or torn off, and the rough protrusions on the rough

surface of geomembrane being worn flat during the shearing process. The failure mode of the rough surface

geomembrane/geotextile interface is affected by normal stress, the formation process of the rough surface and

the spacing of the protrusions on the rough surface. Generally speaking, the smaller the distance between rough

protrusions, the better the enhancement effect on the shear strength of the interface. However, when the distance

is too close, the rough surface of the geomembrane will become smooth, reducing the effect of rough bumps. The

changes in surface roughness of the rough geomembrane before and after the shear test were determined through

microscopic experiments, and the quantitative relationship between the macroscopic and microscopic scale indicators

of the geomembrane interface was established. Under normal pressure and shear stress, the hydrated bentonite in

the bentonite waterproof blanket will be extruded, weakening the shear strength at the interface between the bentonite

waterproof blanket and other materials. With the increase of normal stress, the extrusion amount of bentonite in the

bentonite waterproof blanket will change. The extrusion phenomenon of hydrated bentonite in bentonite waterproof

blankets is more obvious on the woven fabric side than on the non-woven fabric side.

Although some progress has been made in the research on the interfacial shear characteristics and mechanisms of

geosynthetics, the interfaces between rough geomembranes, smooth geomembranes, geotextiles and bentonite water-

proof blankets have rarely been taken as research objects. Under medium and low atmospheric pressure (< 500kPa)

conditions, the composite lining of rough geomembrane + bentonite waterproof blanket presents a shear failure mode

at the interface of rough geomembrane/bentonite waterproof blanket. The interface shear of the rough geomembrane/

bentonite waterproof blanket covers the interface of the rough geomembrane/geotextile and the effect of bentonite.

The rough geomembrane/geotextile interface covers the smooth geomembrane/geotextile interface and the protruding

effect of the rough geomembrane.