产品介绍:

![1602666528149038.jpg 1-20031Q14208[1].jpg](/static/upload/image/20201014/1602666528149038.jpg)

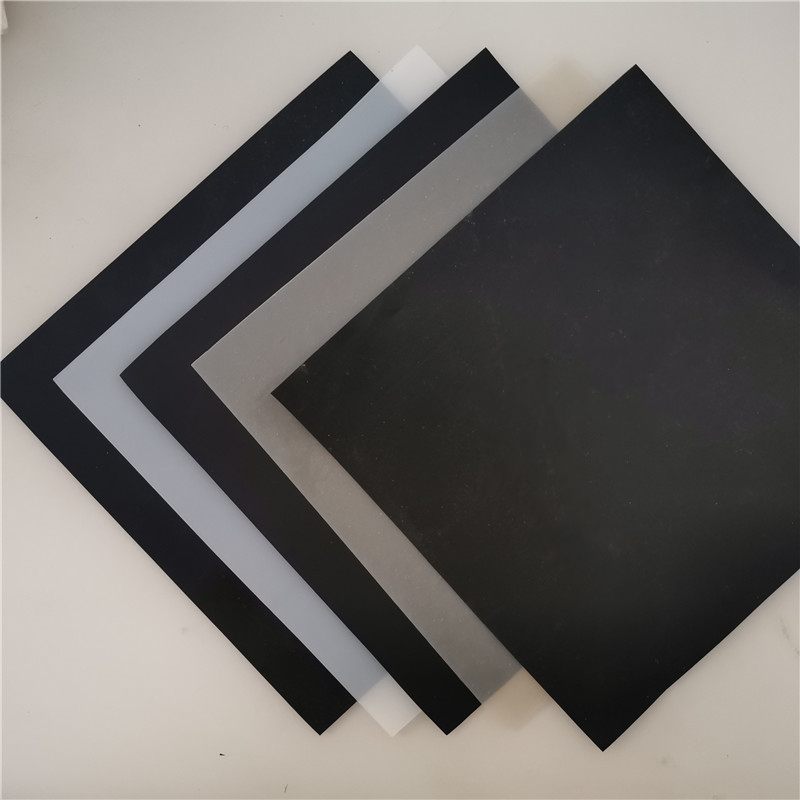

Product Introduction of EVA Tunnel Waterproof Board

The production process of EVA waterproof board adopts the domestic two-stage co-extrusion single-pole

extrusion method. It is made by adding reinforcing agents and antioxidants to the raw resin EVA, followed by

heating and melting, plasticizing, extrusion molding, and traction to form the board. It can also be thermally

synthesized with geotextile (signal layer) with lifting straps to form a composite waterproof board, or it can be

produced by extrusion calendering. The resin is melted and plasticized by the resin extruder, and the molten

sheet blank is extruded from the die opening of the die head slit and fused with the lifting strap. After being

calendered and cooled by the roller, it forms a smooth film, or it is fused with the geotextile with the lifting strap,

and then calendered and cooled by the roller to form a composite waterproof board.